Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

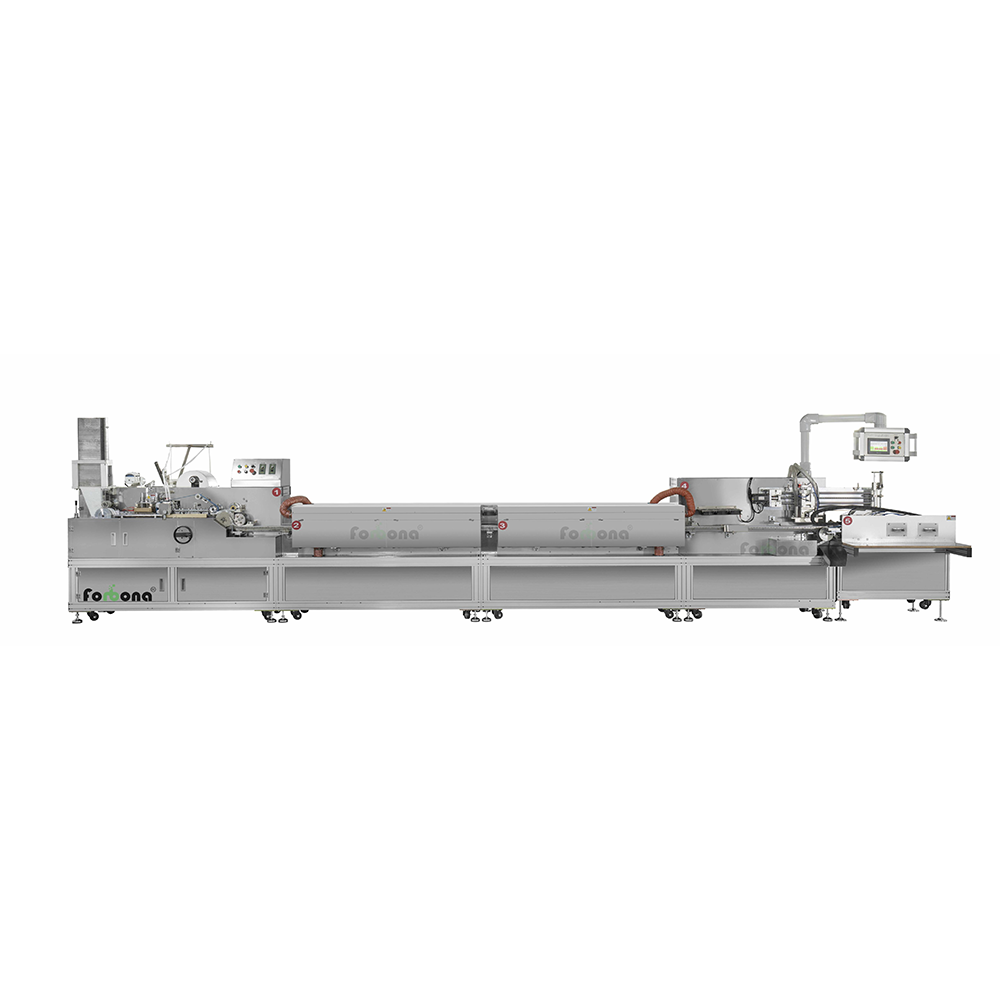

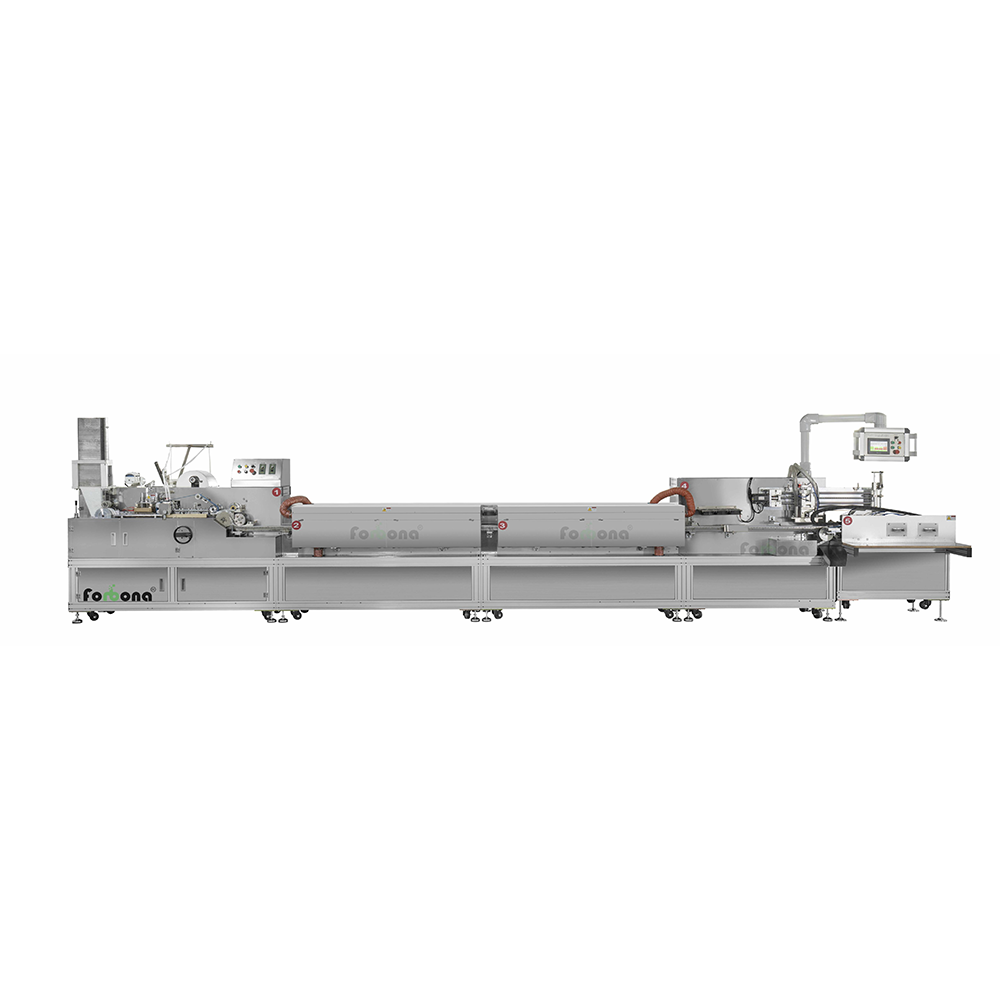

Swab Manufacturing Machine: Backbone of Medical Diagnostics

In the intricate tapestry of healthcare, few tools are as ubiquitous or as critical as the humble swab. From routine check-ups to the detection of infectious diseases, swab manufacturing machines play a pivotal role in producing the tools that enable medical professionals to diagnose and treat with speed and accuracy. As we navigate through a world where health and safety are of paramount concern, the importance of reliable and efficient swab production cannot be overstated. This comprehensive blog aims to shed light on the world of swab manufacturing machines, exploring their significance, the technology behind them, and their role in shaping the future of medical diagnostics.

The Unsung Heroes of Healthcare: Swabs

When we think of medical breakthroughs, we often envision cutting-edge surgeries or groundbreaking pharmaceuticals. Yet, the simple swab, with its ability to collect samples for analysis, is a workhorse of modern medicine. It is the silent partner in the quest for health, playing a crucial role in everything from COVID-19 testing to routine screenings. But how are these indispensable tools made? The answer lies in the precision and efficiency of swab manufacturing machines.

The Technology Behind Swab Manufacturing

The production of swabs may seem straightforward, but it is a process that requires precision, cleanliness, and adherence to strict quality control standards. Swab manufacturing machines are designed to meet these demands, ensuring that each swab is up to the task when it comes to sample collection.

1. Materials Handling

Swabs are typically made from materials like cotton, polyester, or synthetic fibers, which are fed into the machine. The choice of material can depend on the specific requirements of the test or procedure.

2. Cutting and Shaping

Once the material is in place, swab manufacturing machines cut and shape the swab to the desired form. This process must be precise to ensure consistency across all swabs produced.

3. Attachment

The swab head must then be securely attached to a plastic or wooden stick, which is the handle used by medical professionals during sampling.

4. Sterilization

Given the medical application of swabs, it is crucial that they are free from contaminants. Swab manufacturing machines often incorporate a sterilization process to ensure that each swab is ready for use in a clinical setting.

5. Quality Control

Finally, swab manufacturing machines are equipped with quality control measures to inspect each swab for defects or inconsistencies, ensuring that only the highest quality swabs make it to the medical frontlines.

The Role of Swab Manufacturing Machines in the Medical Industry

The efficiency and reliability of swab manufacturing machines are critical to the medical industry, which relies on a steady supply of high-quality swabs for a variety of tests and procedures.

1. Diagnostics

In the realm of diagnostics, swabs are indispensable. From collecting samples for culture and sensitivity tests to the detection of viruses like influenza and SARS-CoV-2, the quality of the swab can directly impact the accuracy of the results.

2. Research and Development

In research settings, swabs are used to collect samples for genetic testing, disease tracking, and the study of various pathogens. The consistency and reliability of the swabs produced by swab manufacturing machines are crucial for the validity of these studies.

3. Forensic Science

Swabs also play a role in forensic science, where they are used to collect trace evidence from crime scenes. The precision of swab manufacturing machines ensures that these swabs are up to the task of collecting even the smallest samples.

The Future of Swab Manufacturing Machines

As technology continues to advance, so too does the capability of swab manufacturing machines. The future of swab production is likely to include:

1. Automation

Increased automation in the manufacturing process can lead to greater efficiency and reduced production times, ensuring a steady supply of swabs when they are needed most.

2. Customization

Advancements in swab manufacturing machines may allow for greater customization in swab design, catering to the specific needs of different tests and procedures.

3. Sustainability

With growing concerns about environmental impact, future swab manufacturing machines may incorporate more sustainable materials and processes, reducing the ecological footprint of swab production.

Conclusion

The world of swab manufacturing machines may not be on the front lines of healthcare, but their role is no less critical. These machines are the silent workhorses of medical diagnostics, producing the tools that enable healthcare professionals to detect, diagnose, and treat a myriad of conditions. As we continue to navigate the complexities of healthcare, the importance of reliable and efficient swab production will only grow, making swab manufacturing machines an essential part of our medical infrastructure.